Freepik.com

Joyce Shamini and Sheena Wong

Being a global engineering and construction company, we have been awarded multiple contracts from around the world.

Click on the following tab for an overview of our various work updates!

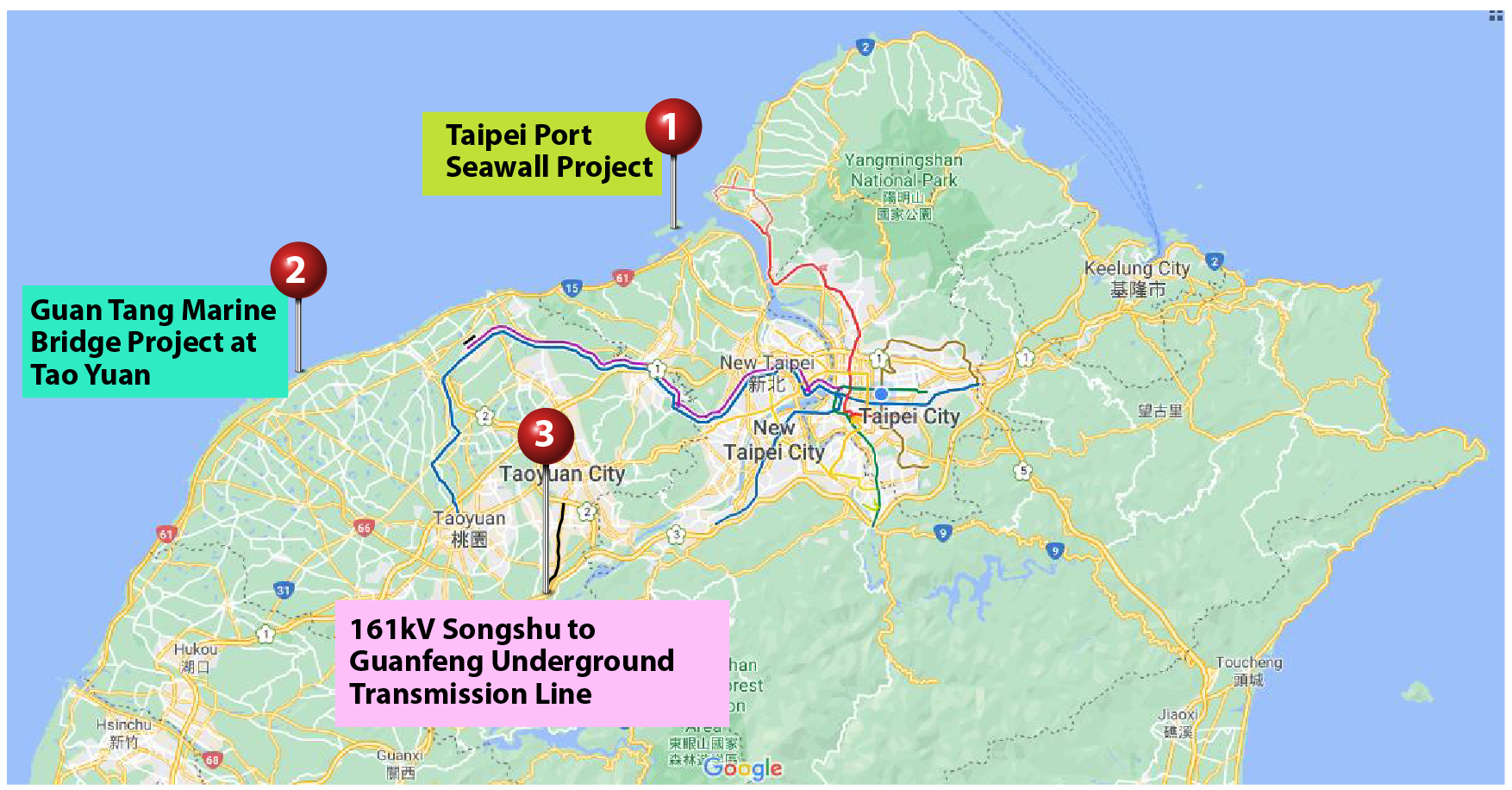

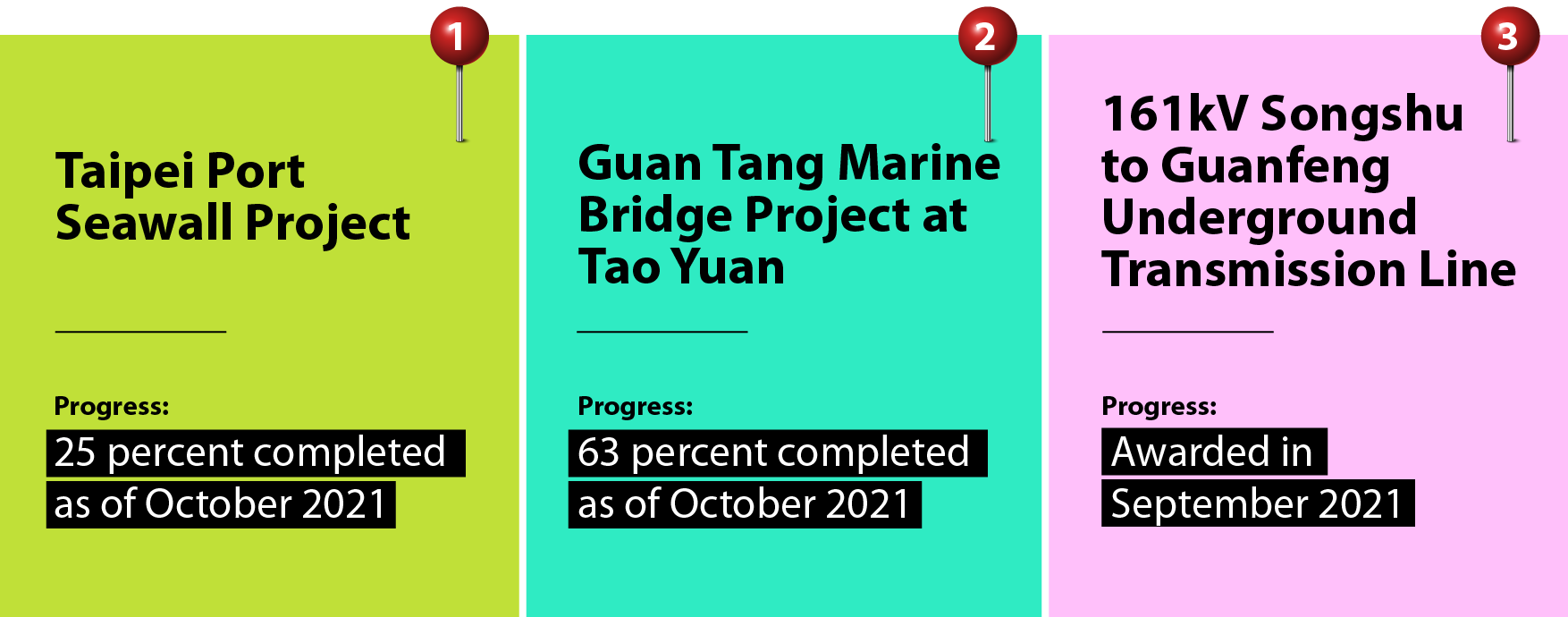

In Taiwan, two projects are ongoing. First is the construction of a 1.23km long marine bridge connecting a Liquefied Natural Gas (LNG) Tank to a LNG Terminal while another is the construction of a 4km long seawall at Taipei Port.

Speaking to Project Director, Eric Foong and Construction Manager, Goh Kim Meng, we found out that the caisson blocks making up the seawalls are some of the largest in Taiwan, some at 19m tall and weighing as much as 8,600 tonnes per unit! Manufactured onshore, the precast blocks will be laid onto the seabed using the caisson construction method and backfilled with gravel and sand. A total of 117 blocks will be constructed.

The extensive scale of the project also requires mega equipment. To haul the precast caissons from the casting yard to its deep-water destination, a 11,000-tonne floating dock is used. The project team also procured the largest dipper dredger in Taiwan, machinery for excavating over water with booms reaching 26m deep. The dipper dredger is used to prepare the seabed foundation before launching the precast caisson blocks into permanent location, forming the seawall.

We had recently secured a new project worth RM463 million to construct a 161kV underground transmission line. At 7 km length, the scope of work involved open trench excavation, pipe jacking works and bored tunnelling method. Kudos to the project team!

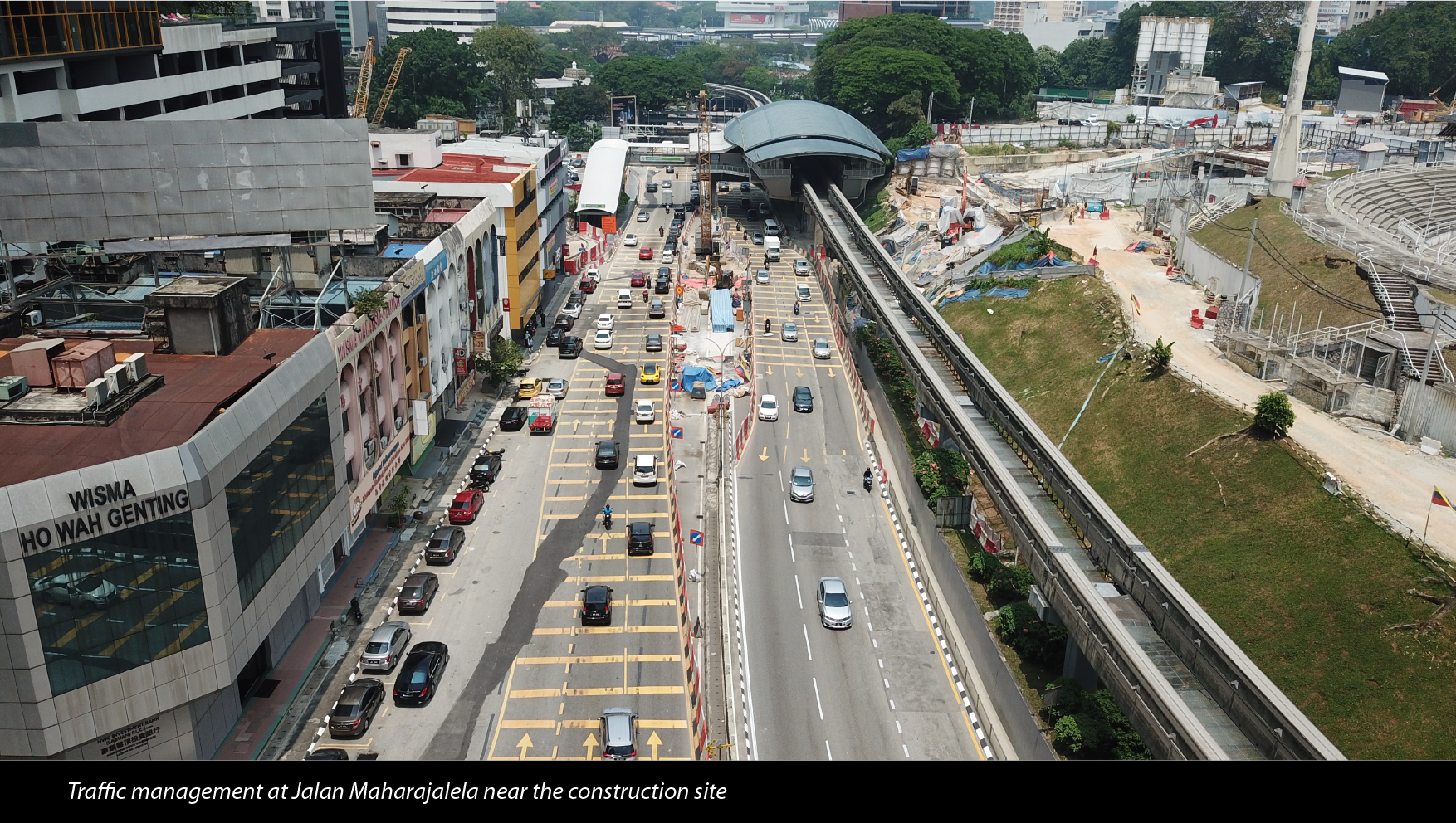

The Belfield project is a stacked roadway tunnel built via the cut-and-cover method connecting Jalan Syed Putra to the PNB 118. Located within the vicinity of DBKL premises, KL and Selangor Chinese Assembly Hall and numerous residential apartments, its execution is not as straightforward as it seems.

A popular conduit among locals and tourists, construction progressed under intense public and stakeholder scrutiny. Construction Manager, Law Chuen Ren, said, “We have three road diversion plans within two years, and that entailed a lot of coordination with authorities, stakeholders and 24/7 traffic management.”

Another interesting fact: this was also one of Gamuda Geo Sdn Bhd and Gamuda M&E Sdn Bhd debut project as sub–trade contractors.

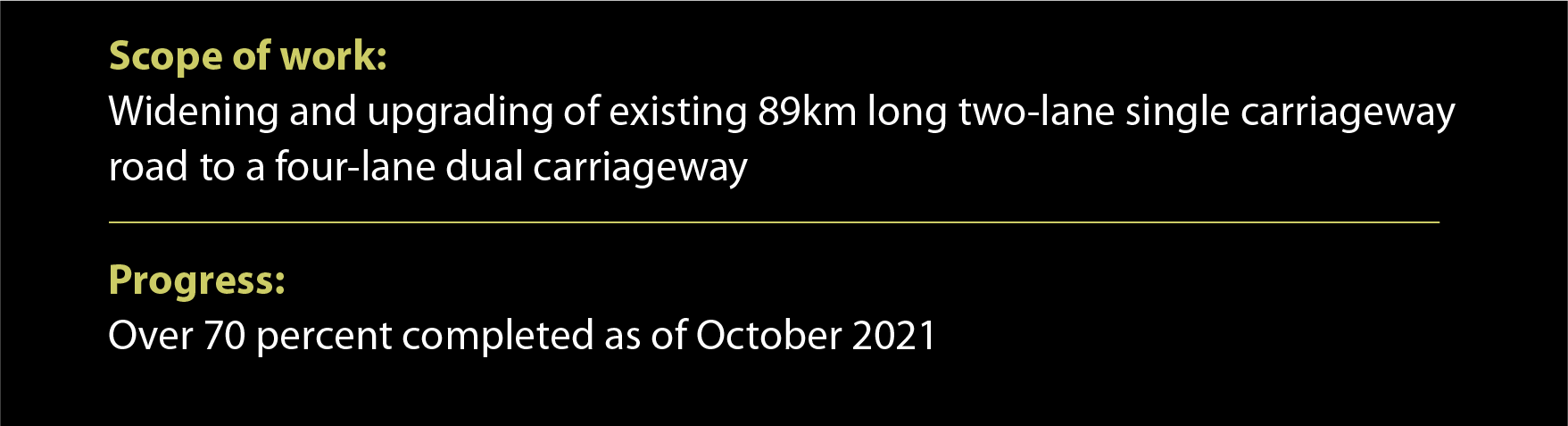

Although separated only by the South China Sea, construction in the East Malaysia is starkly different from Peninsular Malaysia.

Project Director, Deric Kua, learnt that apart from the difference in the local market and supply chain, culturally, Sarawakians work

on the basis of trust and camaraderie. While still recovering from the impact of the COVID-19 pandemic, the project also underwent

a contract change midway, where the project delivery partner (PDP) model was converted into a lump sum contract. Despite these challenges, the team is gearing towards project completion by September 2022.

In the north part of Singapore, the project site geology is classified as a strong Bukit Timah granite formation. Project Director, Eddi Rimba said, “Such inherent geological characteristics were very challenging to build our foundation works. We had to conduct the Ultimate Pile Load Test using the Kentledge system with an incredible 350 percent Pile Working Load to fully mobilise the rock skin friction.” As a result, the team was able to reduce an overall 25 percent of rock coring length with better rock skin friction and bearing capacity.

Another architectural highlight is the use of skim coating as the main base coat, instead of adding the thickness by plastering the walls – a more productive method without risk of defect to achieve higher buildability scores. The team also favours using lightweight precast wall panels for construction.

Apart from awarded jobs, Gamuda Land Vietnam joined hands with the Vietnam government to construct a 600m road connecting Tam Trinh Street to Hanoi’s COVID-19 Treatment Hospital. The urgency led to the rapid deployment of our construction machinery and equipment to the site. The team also mobilised manpower by several shifts to ensure the construction site could work 24/7, while adhering strictly to the COVID-19 protocols.

The team’s quick response and full corporation with the local authority have won high praise from the Prime Minister of Vietnam, Pham Minh Chinh, for completing the construction on schedule and participating in the country’s fight against the pandemic. It was also a great opportunity to fuel future collaboration with the government and demonstrate that we walk the talk in contributing to the community’s interest and benefit.

Special thanks to Yi Hiing (Pan Borneo Project Manager), Chin Sau Lun (Belfield project Construction Manager) and Mai Nam Phuong (Gamuda City Marketing and Brandcom Manager) for contributing pictures and information for this story.